تصميم نظام التصنيع الرشيق باستخدام خارطة تدفق القيمة

دراسة حالة في مصنع اطارات الديوانية

الملخص

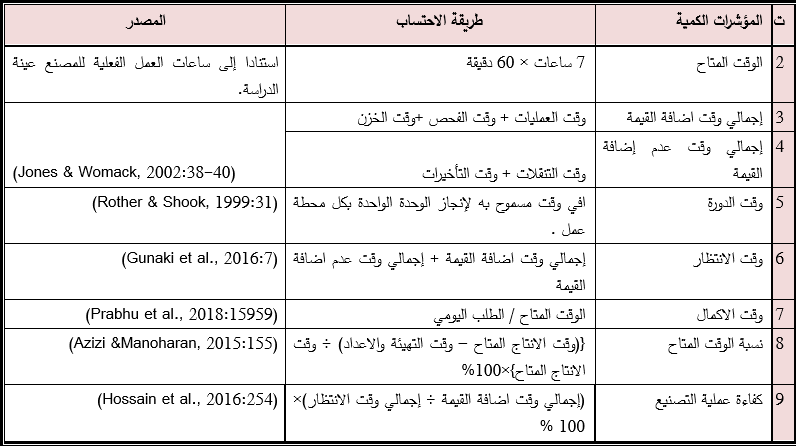

تهدف هذه الدراسة إلى تصميم نظام للتصنيع الرشيق باستعمال احد اهم ادواته الا وهي خارطة تدفق القيمة في تحديد وإزالة أو تبسيط الخطوات والانشطة التي لا تضيف قيمة كأسلوب لتحسين الانتاجية في المنظمة موقع الدراسة ، اذ مكن استعمال خارطة تدفق القيمة في مسار تصنيع الاطار في المصنع موقع الدراسة في الكشف عن مختلف مناطق الهدر التي سببت اوقات انتظار طويلة اثرت سلباً في إنتاجية المصنع.

تمثلت المشكلة التطبيقية للدراسة في طول وكثرة الانشطة والاجراءات المعتمدة في تصنيع الاطار ذات الحجم (1200-20) ، مما ادى إلى طول اوقات الانتظار وارتفاع الكلفة وانخفاض الانتاجية .

اعتمدت الدراسة في جانبها التطبيقي في تحليل الوضع الحالي في المنظمة موقع الدراسة لخط تصنيع الاطار (ذات الحجم 1200-20 ) عن طريق خرائط تدفق القيمة الحالية عن طريق استعمال احد ادواتها وهي خارطة نشاط العملية .

اتبعت الدراسة منهج دراسة الحالة في مصنع اطارات الديوانية ، وجُمعت البيانات والمعلومات عن طريق المعايشة الميدانية والمقابلات التي اجراها الباحثين مع المسؤولين في المصنع وتحديد العمليات والانشطة الحالية لعينة الدراسة المتمثلة بخط تصنيع الاطارات ذات الحجم 1200-20 ، وكان من اهم الاستنتاجات التي توصلت اليها الدراسة :

- اثبتت الدراسة ان استعمال خارطة تدفق القيمة المستقبلية (المقترحة) يسهم في تخفيض اوقات ( اضافة القيمة ، عدم اضافة القيمة ،العملية ،الانتظار، وقت الدورة ، وخزين تحت التشغيل ) في المصنع عينة الدراسة ، فضلا عن خفض التكاليف وتحسين الانتاجية.

ومن اهم التوصيات التي توصلت اليها الدراسة :

- ضرورة تطبيق خارطة تدفق القيمة في المصنع للاستفادة من المعلومات التي توفرها عن الانشطة والاجراءات التي لا تضيف قيمة ما يسهم بشكل كبير في تحديد الهدر والقضاء عليه .

المراجع

A- Book

- Bicheno, J., & Holweg, M. (2009). The Lean toolbox: The Essential guide to lean transformation (4thEd). Buckingham: Picsie .

- Eaton, M. (2013). The Lean Practitioner’s Handbook. Kogan Page Limited.

- Hines, P., Founf, P., Griffiths, G., & Harrison, R. (2008). Staying Lean : Thriving , Not Just Surviving. Lean Enterprise Research Centre.

- Hines, P., Found, P., Griffiths, G., & Harrison, R. (2011). Staying Lean Thriving, Not Just Surviving (2nd Ed). CRC Press.

- Husby, P. C., & Hamilton, P. C. H. J. (2018). Make Your Business a Lean Business How to Create Enduring Market Leadership. CRC Press.

- Jackson, T. L. (2013). Mapping Clinical Value Streams Rona Consulting Group & Productivity Press Thomas. CRC Press.

- Jacobs, F. R., & Chase, R. B. (2008). Operations and Supply Management: The Core. McGraw-Hill/Irwin.

- Jacobs, F. R., & Chase, R. B. (2018). Operation And Supply Chain Management (15th Ed). McGraw-Hill Education.

- Keyte, B., & Locher, D. A. (2016). The Complete Lean Enterprise Value Stream Mapping for Office and Services (2nd Ed). CRC Press Taylor & Francis Group.

- Lareau, W. (2011). Office Kaizen :Harnessing Leadership, Organizations, People, and Tools for Office Excellence (2nd Ed). ASQ Quality Press .

- Liker, J. K., & Meier, D. (2006). The Toyota Way Fieldbook A Practical Guide for Implementing Toyota’s 4Ps. McGraw-Hill.

- Locher, D. A. (2008). Value Stream Mapping for Lean Development A How-To Guide for Streamlining Time to Market. CRC Press.

- Rich, N., Bateman, N., Esain, A., Massey, L., & Samuel, D. (2006). Lean Evolution Lessons from the Workplace. Cambridge University Press.

- Rother, M., & Shook, J. (1999). Learning to See: Value Stream Mapping to Create Value and Eliminate Muda. The Lean Enterprise Inst., Brookline, Mass.

- Santos, J., Wysk, R., & Torres, J. M. (2006). Improving Production with Lean Thinking. John Wiley & Sons, Inc.

- Schroeder, R. G., & Goldstein, S. (2018). Operations Management in the Supply Chain: Decisions and Cases (7th Ed). McGraw-Hill Education.

- Slack, N., Brandon-Jones, A., & Johnston, R. (2016). Operations Management (8th Ed). Pearson Education Limited.

- Stern, T. V. (2017). Lean and Agile Project Management. CRC Press.

- Womack, J. P., & Jones, D. T. (2003). Lean thinking—banish waste and create wealth in your corporation: Revised and Updated. Free Press.

B- Thesis's & Dissertations

- Rathilall, R. (2011). Improving quality and productivity through lean manufacturing at an automotive manufacturing organization in Durban (Doctoral dissertation, Durban University of Technology).

- Sabet-rasekh, A. (2014). Design of a Lean Manufacturing System for the Production of Compliant Wind at Sparton Electronics. Master Thesis within Mechanical Engineering, Embry-Riddle Aeronautica University).

- Terzic, M., & Pitzalis, F. (2017). How to be Lean and Sustainable - A startup perspective (Master Thesis within Business Administration, JÖNKÖPING University).

C- Journals & Periodicals

- Alves, A. C., Dinis-Carvalho, J., & Sousa, R. M. (2012). Lean production as promoter of thinkers to achieve companies’ agility. The Learning Organization, 19(3), 219–237.

- Andersson, R., Eriksson, H., & Torstensson, H. (2006). Similarities and differences between TQM , six sigma and lean. The TQM Magazine, 18(3), 282–296.

- Arnheiter, E. D., & Maleyeff, J. (2005). The integration of lean management and Six Sigma. The TQM Magazine, 17(1), 5–18.

- Atieh, A. M., Kaylani, H., Almuhtady, A., & Al-Tamimi, O. (2016). A value stream mapping and simulation hybrid approach: application to glass industry. International Journal of Advanced Manufacturing Technology, 84(5–8), 1573–1586.

- Azizi, A., & Manoharan, T. a/p. (2015). Designing a Future Value Stream Mapping to Reduce Lead Time using SMED-A Case Study. Procedia Manufacturing, 2(February), 153–158.

- Bhasin, S., & Burcher, P. (2006). Lean viewed as a philosophy. Journal of Manufacturing Technology Management, 17(1), 56–72.

- Chowdary, B. V, & George, D. (2012). Improvement of manufacturing operations at a pharmaceutical company A lean manufacturing approach. Journal of Manufacturing Technology Management, 23(1), 56–75.

- Chowdhury, A. H., Shahriar, S., Hossen, T., & Mahmud, P. (2017). Reduction of Process Lead Time Using Lean Tool - Value Stream Mapping ( VSM ). Applied Mechanics and Materials, 860, 74–80.

- Cooney, R. (2002). Is ``lean’’ a universal production system? Batch production in the automotive industry. International Journal of Operations & Production Management, 22(10), 1130–1147.

- Dankbaar, B. (1997). Lean Production : Denial , Con firm ation or Extension of Sociotechn ical Systems Design ? Human Relations, 50(5), 567–584.

- Das, B., Venkatadri, U., & Pandey, P. (2014). Applying lean manufacturing system to improving productivity of airconditioning coil manufacturing. Int J Adv ManufTechnol, 71(1–4), 307–323.

- Dilanthi, M. G. S. (2014). Empirical Progression of Lean Manufacturing : Literature Review. International Journal of Engineering Research, 3(11), 657–661.

- Gunaki, P., Teli, S. N., & Bhushi, U. M. (2016). Reduction of Cycle Time with the Application of Value Stream Mapping and Simulation in Die Casting Industry. ISDSI International Conference, 1–13.

- Gupta, S., & Jain, S. K. (2013). A literature review of lean manufacturing Shaman. International Journal of Management Science and Engineering Management, 8(4), 241–249.

- Gurumurthy, A., & Kodali, R. (2011). Design of lean manufacturing systems using value stream mapping with simulation A case study. Journal of Manufacturing Technology Management, 22(4), 444–473.

- Hallgren, M., & Olhager, J. (2009). Lean and agile manufacturing : external and internal drivers and performance outcomes. International Journal of Operations & Production Management, 29(10), 976–999.

- Hines, P., Holweg, M., & Rich, N. (2004). Learning to Evolve : A Review of Contemporary Lean Thinking. International Journal of Operations &Production Management, 24(10), 994–1011.

- Hines, P., & Rich, N. L. (1997). The Seven Value Stream Mapping Tools. International Journal of Operations &Production Management, 17(1), 46–64.

- Hodge, G. L., Ross, K. G., Joines, J. A., & Thoney, K. (2011). Adapting lean manufacturing principles to the textile industry. Production Planning & Control, 22(3), 237–247.

- Hopp, W. J., & Spearman, M. L. (2004). To Pull or Not to Pull : What Is the Question ? Maufacturing & Serves Operations Management, 6(2), 133–148.

- Hossain, M. M., Hossain, D., Hossain, M. A., Ahmad, F., Hoque, M. M., & Rahman, M. (2016). Lead Time Reduction and Process Cycle Improvement of an Ice-cream Manufacturing Factory in Bangladesh by Using Value Stream Map and Kanban Board : A Case Study. Australian Journal of Basic and Applied Sciences, 10(15r), 250–260.

- Ihueze, C. C., & Okpala, C. C. (2014). The Tools And Techniques Of Lean Production System Of Manufacturing. International Journal of Advanced Engineering Technology, V(IV).

- Jasti, N. V. K., & Sharma, A. (2014). Lean manufacturing implementation using value stream mapping as a tool : A case study from auto components industry. International Journal of Lean Six Sigma, 5(1), 89–116.

- Kumar, S. (2014). Lean Manufacturing and its Implementation. International Journal of Advanced Mechanical Engineering, 4(2), 231–238.

- Lacerda, A. P., Xambre, A. R., & Alvelos, H. M. (2016). Applying Value Stream Mapping to eliminate waste: A case study of an original equipment manufacturer for the automotive industry. International Journal of Production Research, 54(6), 1708–1720.

- Lasa, I. S., Castro, R. De, & Laburu, C. O. (2009). Extent of the use of Lean concepts proposed for a value stream mapping application. Production Planning & Control, 20(1), 37–41.

- Librelato, T. P., Lacerda, D. P., Rodrigues, L. H., & Veit, D. R. (2014). A process improvement approach based on the Value Stream Mapping and the Theory of Constraints Thinking Process. Business Process Management Journal, 20(6), 922–949.

- Liker, J. K., & Wu, Y.-C. J. (2000). Japanese Automakers, U.S. Suppliers and Supply-Chain Superiority. Sloan Management Review, 81--93.

- Matt, D. T. (2014). Adaptation of the value stream mapping approach to the design of lean engineer-to-order production systems. Journal of Manufacturing Technology Management, 25(3), 334–350.

- Mcdonald, T., Aken, E. M. Van, & Rentes, A. F. (2002). Utilising Simulation to Enhance Value Stream Mapping : A Manufacturing Case Application. International Journal of Applications : A Leading Journal of Supply Chain, 5(2), 37–41.

- Mohanraj, R., Sakthivel, M., Vinodh, S., & Vimal, K. E. K. (2015). A framework for VSM integrated with Fuzzy QFD. The TQM Journal, 27(5), 616–632.

- Prabhu., M., .V, V., Manoj.S, & Jangiraman, R. (2018). Line Balancing Technique for Labour Optimisation and Productivity Improvement. International Journal of Engineering Science and Computing, 8(1), 15957–15960.

- Serrano Lasa, I., Ochoa Laburu, C., & de Castro Vila, R. (2008). An evaluation of the value stream mapping tool. Business Process Management Journal, 14(1), 39–52.

- Seth, D., Seth, N., & Dhariwal, P. (2017). Application of value stream mapping (VSM) for lean and cycle time reduction in complex production environments: a case study. Production Planning & Control, 28(5), 398–419.

- Shah, R., & Ward, P. T. (2003). Lean manufacturing: context, practice bundles, and performance. Journal of Operations Management 21, 21(2), 129–149.

- Simpson, D. F., & Power, D. J. (2005). Use the Supply Relationship to Develop Lean and Green Suppliers. 2005, 10(1), 60–68.

- Singh, H., & Singh, A. (2013). Application of lean manufacturing using value stream mapping in an auto‐parts manufacturing unit. Journal of Advances in Management Research, 10(1), 72–84.

- Sreerengan, V. R., Abh, S., & Ram, R. (2017). Value Stream Mapping In Lean Management Concept. International Journal of Advanced Research in Management and Social Sciences, 6(5), 90–101.

- Sundar, R., Balaji, A. N., & Satheeshkumar, R. M. (2014). A Review on Lean Manufacturing Implementation Techniques. Procedia Engineering, 97, 1875–1885.

- Sultana, M., & M.M Nazrul Islam. (2013). Scope of Value Stream Mapping to Initiate Lean Manufacturing: An Analysis in the Apparel Industry of Bangladesh. International Journal of Lean Thinking, 4(1).

- Taj, S. (2008). Lean manufacturing performance in China : assessment of 65 manufacturing plants. Journal of Manufacturing Technology Management, 19(2), 217–234.

- Taj, S., & Morosan, C. (2011). The impact of lean operations on the Chinese manufacturing performance. Journal of Manufacturing Technology Managemen, 22(2), 223–240.

- Urban, W. (2015). Organizational culture assessment as a means of Lean Management maturity diagnosis. Zarz1dzanie i Finanse Journal of Management and Finance, 13(4), 131–139

-Vinodh, S., Arvind, K. R., & Somanaathan, M. (2010). Application of value stream mapping in an Indian camshaft manufacturing organisation. Journal of Manufacturing Technology Management, 21(7), 888–900.

- Womack, J. P., & Jones, D. T. (1996). Beyond Toyota : How to Root Out Waste and Pursue Perfection. Harvard Business Review, 74(5), 140–158

D-Conferences

- Howell, G.A. (1999).What is lean construction-1999?. Seventh Conference of the International Group for Lean Construction, University of California, Berkeley, CA.USA,7,1-10.

- Tortorella, G. L., Vergara, L. L., Ferreira, E. P., & Fries, C. E. (2016). Lean manufacturing and socio-technical and ergonomics practices implementation. International Conference on Industrial Engineering and Operations Management, 72–84.

التنزيلات

منشور

كيفية الاقتباس

إصدار

القسم

الرخصة

الحقوق الفكرية (c) 2024 محمود فهد عبد علي الدليمي ، بشرى عبد الحمزة عباس الربيعي

هذا العمل مرخص بموجب Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

يحتفظ المؤلفون بحقوق الطبع والنشر لأوراقهم دون قيود.