The impact of smart maintenance in improving industrial performance

(An analytical study in the General Company for the Automotive Industry – Alexandria)

Keywords:

smart maintenance, industrial performance, General Company for Automotive Industry / Alexandria.Abstract

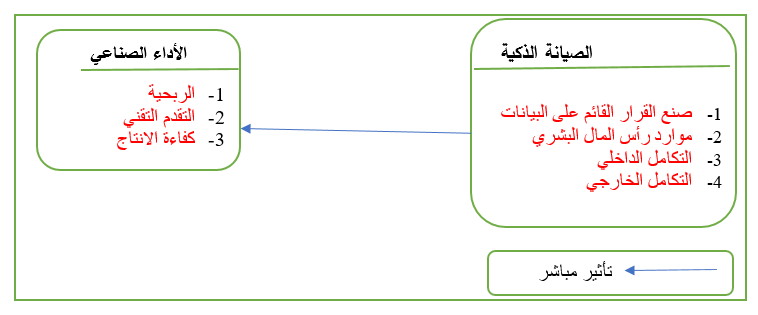

The research aims mainly to determine the impact of smart maintenance in improving industrial performance at the level of the General Company for the Automotive Industry - Alexandria. And based on a major problem that was diagnosed with several questions. The extent to which the influencing relationships between variables are realized in the field. An expressive intellectual framework has been formed for the research. Smart maintenance was adopted as an independent variable. It consists of four dimensions (Data-driven decision-making - Human capital resource - Internal integration - External integration). Industrial performance was adopted as a dependent variable. Which consists of three dimensions (profitability - technical progress - production efficiency). And the sample was formed. Of the workers in the General Company for the Automotive Industry, their number is (72). workers. (engineers and technicians). To analyze the data, a set of statistical methods were used. Available in the statistical program (SPSS.V.25). The research reached several conclusions, including (the great importance of the impact of smart maintenance on many aspects related to production processes to keep pace with the great developments in industrial environments, to be reflected in raising the level of industrial performance). The search resulted in a set of recommendations. Among them (the General Company for Automotive Industry - Alexandria should develop a system that shows the most appropriate maintenance and repair methods and instructions while monitoring the condition of all targeted equipment and machines using smart methods and work to prevent unexpected breakdowns and unplanned disturbances while increasing the reliability of the system in order to prevent potential damage due to equipment failure).

References

Adetayo, J.O.( 2013),. Management of foreign exchange risks in a selected commercial bank in Nigeria, Journal of Social Science, Vol. 8, No. 3,.

Alsyouf , Imad ,( 2004) Cost Effective Maintenance for Competitive Advantages, degree of Doctor of Philosophy ,(Terotechnology) School of Industrial Engineering, Växjö University, Sweden..

Barasara , Rajanish ,( 2013),. An Analytical Study of Capital structure Vis – A – Vis Profitability of Banking Industry in India, degree of Doctor of philosophy , Saurashtra University,

Berrah, L., Cliville, V., Trentesaux, D., & Chapel, C. (2021). Industrial Performance: An Evolution Incorporating Ethics in the Context of Industry 4.0. Sustainability, 13(16), 9209

Bhattacharjea, A. (2006). Labour market regulation and industrial performance in India: A critical review of the empirical evidence. Indian Journal of Labour Economics, 49(2), 211-232.

Bititci, U., Cocca, P., & Ates, A. (2016). Impact of visual performance management systems on the performance management practices of organisations. International Journal of Production Research, 54(6), 1571-1593.

Bokrantz, J., & Skoogh, A. (2023). Adoption patterns and performance implications of Smart Maintenance. International Journal of Production Economics, 256, 108746.

Bokrantz, J., Skoogh, A., Berlin, C., Wuest, T., & Stahre, J. (2020). Smart Maintenance: an empirically grounded conceptualization. International Journal of Production Economics, 223, 107534.

Bokrantz, J., Skoogh, A., Berlin, C., Wuest, T., Stahre, J., (2020c),. Smart Maintenance: an empirically grounded conceptualization. Int. J. Prod. Econ. 223.

Candell, O., Karim, R., & Söderholm, P. (2009). eMaintenance—Information logistics for maintenance support. Robotics and Computer-Integrated Manufacturing, 25(6), 937-944.

Carnero, M. C. (2005),. Selection of Diagnostic Techniques and Instrumentation in a Predictive Maintenance Program. A Case Study. Decision Support Systems, 38, 539-555.

CEN, (2022) ,"Maintenance Terminology" , European Committee for Standardization Brussels, EN 13306.

Cheng, S., Azarian, M. H., & Pecht, M. G. (2010). Sensor systems for prognostics and health management. Sensors, 10(6), 5774-5797.

Emara, M., The impact of technological progress on employment in Egypt, International Journal of Social Economics, vol. 48, No. 2 , 2020.

Fugate, Brian S., John T. Mentzer, Stank T. P.,( 2010),. Logistics Performance: Efficiency, Effectiveness, and Differentiation: Journal of Business Logistics , vol 31, No.1,.

Fumagalli, L., Macchi, M., Colace, C., Rondi, M. & Alfieri, A. (2016),. A Smart Maintenance Tool for a Safe Electric Arc Furnace. IFAC-PapersOnLine, 49, 19-24.

Graeml, A. R., Peinado, J., (2011), Measuring Logistics Performance: the Effectiveness of Mmog /Le as Perceived by Suppliers in the Automotive Industry, Journal of Operations and Supply Chain Management, vol.4, No.1,

Guo Bin ,( 2008),. Technology acquisition channels and industry performance: An industry-level analysis of Chinese large- and medium-size manufacturing enterprises,.

Guoa,Z., Zhoua,D., Zhoua,Q., Zhang ,X., Geng,X., Zeng,Z., Lva,C., Hao, A.,( 2020), Applications of virtual reality in maintenance during the industrial product lifecycle: A systematic review , Journal of Manufacturing Systems , Vol.56 ,

Han, J., Li, T., & Philbin, S. P. (2023). Does low-carbon pilot policy in China improve corporate profitability? The role of innovation and subsidy. Innovation and Green Development, 2(2), 100050.

Heizer, J., Render, B., & Munson, C., (2017), "Operations Management Sustainability and Supply Chain Management", twelfth Edition., Pearson Education, USA.

Hernández, Y., Monagas, C., de Lara, D. R. M., & Corral, S. (2023). Are microgrids an opportunity to trigger changes in small insular territories toward more community-based lifestyles?. Journal of Cleaner Production, 411, 137206.

Holgado, M. & Macchi, M.( 2014 ),. Exploring the Role of E-Maintenance for Value Creation in Service Provision. Engineering, Technology and Innovation (ICE), International ICE Conference on, 2014. IEEE, 1-10.

Hung, M. H., Chen, K. Y., Ho, R. W., & Cheng, F. T. (2003). Development of an e-diagnostics/maintenance framework for semiconductor factories with security considerations. Advanced Engineering Informatics, 17(3-4), 165-178.

Jambekar, A., Classification scheme for lean manufacturing tools, International Journal Production Research, vol. 41,No.13, 2008

Jimenez, J. F., Berrah, L., Trentesaux, D., & Chapel, C. (2022). Towards the ethical awareness integration on industrial performance management systems. IFAC-PapersOnLine, 55(10), 3232-3237.

Kans M, Galar D and Thaduri A. (2015). Maintenance 4.0 in Railway Transportation Industry. Proceedings of the 10th World Congress on Engineering Asset Management (WCEAM 2015) Springer International Publishing, page 317-331, isbn 978-3-319-27064-7.

Kao, C., Chen, M.,( 2020), Employee downsizing, financial constraints, and production efficiency of firms , International Review of Economics and Finance, Vol. 68,.

Khrawish, H.A.,(2011),. Determinants of commercial banks performance: evidence from Jordan, International Research Journal of Finance and Economics, Vol. 5, No. 5,.

Krajewski, Judie & Malhotra, Maya& Ritzman, Barbara (2016), " Operations Management", Eleventh Edition, United States of America.

Kumar, U. & Galar, D.( 2018). Maintenance in the Era of Industry 4.0: Issues and Challenges. In: Quality, It and Business Operations. Springer. 231-250.

Lee, J., Jin, C., Liu, Z. & Ardakani, H. D. (2017). Introduction to Data-Driven Methodologies for Prognostics and Health Management. In: Probabilistic Prognostics and Health Management of Energy Systems. Springer. 9-32.

Li, K., Lin, B.,( 2016),. Heterogeneity analysis of the effects of technology progress on carbon intensity in China, International Journal of Climate Change Strategies and Management, Vol. 8, No. 1,

Liao, Y., Deschamps, F., Loures, E.D.F.R. and Ramos, L.F.P. (2017), “Past, present and future of industry 4.0-a systematic literature review and research agenda proposal”, International Journal of Production Research, .Vol. 55, pp. 3609-3629.

Lindberg ,C., Tan ,S., Yan ,J., Starfelt ,F.,( 2015),. Key performance indicators improve industrial performance , The 7th International Conference on Applied Energy, Energy Procedia Vol.75,.

Lundgren, C., Bokrantz, J., & Skoogh, A. (2021). Performance indicators for measuring the effects of Smart Maintenance. International Journal of Productivity and Performance Management, 70(6), 1291-1316.

Lynch, R. L. & Cross, K. F.,( 1991) “Measure Up! Yardsticks for Continuous , Improvement”, Basil Blackwell, Oxford ,.

Maina, P.,( 2015),. Lean Manufacturing Practices and Performance of large scale Manufacturing Firms in Nairobi, Kenya, Degree of Masters, School of Business University of Nairobi ,.

Márquez, A. C., de León, P. M., Fernández, J. G., Márquez, C. P., & Campos, M. L. (2009). The maintenance management framework: A practical view to maintenance management. Journal of Quality in Maintenance Engineering, 15(2), 167-178.

Mensah, E. B., Owusu, S., & Foster-McGregor, N. (2023). Productive efficiency, structural change, and catch-up within Africa. Structural Change and Economic Dynamics, 65, 78-100.

Murthy, Y. & Sree, R.( 2011),. A study on financial ratios of major commercial banks, Research Studies, College of Banking and Financial Studies, Sultanate of Oman, Vol. 3, No. 2, 2003.

Ojeda, L., Genevois, C. E., & Busch, V. (2023). Novel flours from leguminosae (Neltuma ruscifolia) pods for technological improvement and nutritional enrichment of wheat bread. Heliyon.

Pérez-Blanco, C. D., Sapino, F., & Saiz-Santiago, P. (2023). First-degree price discrimination water bank to reduce reacquisition costs and enhance economic efficiency in agricultural water buyback. Ecological Economics, 205, 107694.

Qiao, G. & Weiss, B. A. (2016),. Advancing Measurement Science to Assess Monitoring, Diagnostics, and Prognostics for Manufacturing Robotics. International journal of prognostics and health management, 7.

Richard, P.J., Devinney, T.M., Yip, G.S., Johnson, G.,( 2009),. Measuring Organizational Performance as a Dependent Variable: Towards Methodological Best Practice ,.

Roda, I., & Macchi, M. (2021). Maintenance concepts evolution: A comparative review towards advanced maintenance conceptualization. Computers in Industry, 133, 103531.

Saha,D., Syamsunder , M., Chakraborty,S.,( 2016),. Manufacturing Performance Management using SAP OEE, Springer Science, Business Media Finance Inc, New York,.

Samuel, V, B., Agamuthu, P., Hashim, M, A.( 2013) , Indicators for assessment of sustainable production: A case study of the petrochemical industry in Malaysia, Ecological Indicators ,Vol. 24,.

Sana, A., (2016),. Cultural Impediments to Technology Development in India , International Journal of Sociology and Social Policy, Vol.10, No.8,.

Slack, Nigel & Jones, Alistair Brandon &Johnston (2016) , " Operations Management" Eighth Edition. Italy, Library of Congress.

Stevenson, William J, (2018) , " Operations Management" Thirteenth edition , New York, Library of Congress.

Tortorella, G. L., Fogliatto, F. S., Cauchick-Miguel, P. A., Kurnia, S., & Jurburg, D. (2021). Integration of industry 4.0 technologies into total productive maintenance practices. International Journal of Production Economics, 240, 108224.

Velasco ,S., (2019), Competitiveness and production efficiency across OECD countries , International Business Journal, Vol. 29, Issue: 2 .

Vukovic, D. B., Spitsina, L., Spitsin, V., & Gribanova, E. (2023). The joint impact of working capital and platform-economy on firm profitability: The case of e-business model in transition country. Journal of Open Innovation: Technology, Market, and Complexity, 9(2), 100060.

Zhao, T., Pei, R., & Pan, J. (2021). The evolution and determinants of Chinese property insurance companies’ profitability: A DEA-based perspective. Journal of Management Science and Engineering, 6(4), 449-466.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 College of Administer and Economics - Kerbela University

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors retain the copyright of their papers without restrictions.